Don and Al were in this week. Al and I met Don when he came to UAF in 1985 for a year when Al was a fisheries graduate student and I an undergrad. Funny thing is Al and I didn’t know each other then, but met when were were fisheries biologists in Southeast Alaska later on.

Don is up there on the list of most influential people in my life. I knew Don from UAF, although I never took a class from him there. I met him while he took the bus that I drove for my student job from upper to lower campus. He told me about the Peace Corps. He’d gone to Malaysia in the Peace Corps after completing his MS degree. He told me about the advantages I’d have with federal jobs, and that Peace Corps would give me two years of mid-level professional experience. Had I not gone in the Peace Corps, it would take me years of time as a seasonal ADFG technician, or a Master’s degree, just to apply for a mid-level, permanent job with ADFG, which was my goal job after earning my undergraduate degree at UAF. He sold me on the professional job experience aspect of the Peace Corps. I saw the humanitarian experience of working in a developing country as a side-benefit. It certainly wasn’t the reason I went in.

Peace Corps was the most important 2 years of my life. I met fellow volunteers I would never have met had I stayed in Alaska – people from different backgrounds and interests and views. I learned a second language, lived in a rural African village, ate foods mostly grown in the surrounding rain forest, and had my eyes opened on everything from Race to poverty to religion to living by one’s own hand without any modern machinery to “transportation” primarily being one’s two feet to the commonality of fisheries around the world to the worth of fish as a protein in most of the world’s diet to the possibilities of successful tilapia fish farming in rural Africa in ponds built with shovels and feeds found in the bush. You’re just not going to get that and more in your first two years of any job that I know of. Yet I don’t know one person – family, friend, student – that I got to go into the Peace Corps. I think Don may say the same thing – that I was his only one. Sadly, the Peace Corps dropped its fisheries and fish farming program some 20 years ago and I can never get a good answer why from them. They say they only assign volunteers to programs that eh host countries want, yet just about every country the Peace Corps is in will note they don’t have enough fish production to even meet the needs of residents, much less for export. I think Peace Corps dropped the program because the stateside training was expensive. Teaching seems to be the big thing now for Peace Corps Volunteering. Countries like Sierra Leone that pay their teachers little, and often a salary that’s delayed months and months in getting to the teachers, is happy to have a Peace Corps Volunteer teacher who gets paid by the US government on time, and who doesn’t have to have a farm on the side just to get by. I haven’t seen many Peace Corps programs that a more appropriate technology and had a real chance to sustain themselves than fish farming. We worked with farmers to build ponds by hand, fed the ponds water by gravity, used African fish that reproduced right in the pond, and raised a fish- tilapia – that would eat about anything, from termites in their mushroom dirt house available year round in the surrounding country side to the rice bran left over when rice was extracted for everyone’s daily meal that was otherwise thrown away. And for people like me who stayed in the profession here in the states, a couple generations now of fisheries or similar degree college graduates haven’t had the same opportunities I did with the Peace Corps, which is also just plain sad.

Don also told me I’d be part of a Peace Corps community when I returned, and that I’d need them around. Ironically, I maybe came to know how combat veterans like my elder cousins who fought in Vietnam felt when they returned home. I didn’t know what they went through, just how they felt when they got home to their hometown and friends and family – only people who went through what they did knew what it was about, and it was impossible for someone who hadn’t to really understand. Not your parents, not your siblings, not your best friends from high school.

Don kept track of me during and after my Peace Corps stint in Sierra Leone. When I sent him a letter asking just out of casual curiosity what he did at Mississippi State, where he went after his year at UAF and remains today, he took this as an opportunity. He replied with a 3 or 4 page typed letter, outlining the research he was doing there, that he’d love to have me in the program, what I needed to do to apply (like take the MSAT), and that he could offer me a full-ride assistantship if I was accepted. I had no intention of going to grad school, but here was opportunity knocking. And if I’ve learned one thing, it’s the important of saying “yes” when things like this come along.

I’d recently been to a Board of Fish meeting, where a state biologist was going over a tagging study that was relevant to the area I was working in. I was as clueless as most in the crowd as to the workings of the statistical models used in the study, the findings of which were important to the management of salmon in our area. A masters degree program dropped right into my lap was just what I needed to help learn that statistics stuff. Kodiak Community College was, by chance, offering the MSAT exam that Saturday. I grabbed the MSAT informational booklet, completed the practice test in the book over the next two days, and took the exam on Saturday. My score was good, and I was on my way to MSU that August.

Peace Corps again entered the equation. I asked my friend Tom, who was just here in Craig fishing with me, to come up for the ride down. In addition to companionship on the ride, I knew he was mechanically inclined. When we broke the timing belt in Haines Junction in the Yukon Territory, Tom went to work, with me assisting his mysterious instructions, like we got to get the piston to top dead center, and things like that. Luckily, I’d thought to buy a timing belt before I left, and after a few hours, we were back on the road.

MSU was another trip into another culture. I think many of my collegues in Alaska wondered why someone managing Alaska fisheries would want to go to a college in the deep South. I always felt there was a lot of monoculture education the department from Pacific Northwest schools – the U of Washington comes to mind – and I was excited to go somewhere different and learn about different fish in different waters. Like the Peace Corps, it was a great experience of a new place and new ideas and new people. I made some life long friends there. One was the son of a man who worked in the Sierra Leone embassy who I met while I was there. All of us under Don worked our asses off with piles of field work, as well as getting our class work done. We all had assistantships, and nobody working in one of Don’s projects was going to finish if he couldn’t put in 60 to 80 hour weeks between classes and fieldwork. I liked Mississippi. It’s a rural, outdoors culture where most people fish and hunt or know those who do. I worked in the Delta region of Mississippi, where lots of civil rights history was made. I knew I could never live in Mississippi, though. After doing my first summer of field work in 90+ degree blazing sun and high humidity, I knew I’d never want to live in a place like that, having already had experience doing that in Africa. Cold climates are for me. As I told my Sierra Leone friend in Juneau – you can always put on another coat to keep warm if you’re cold, but when it’s hot, you can take all your clothes off, and you’re still hot. He has come to love Alaska, and complains a little bit more each time he returns from Sierra Leone at how hot it is there- the country where he was raised. I still see my Mississippi friends. I welcome them here to fish and as a respite to the heat at home.

When I completed my Masters degree, I had a lot of experience under my belt. I’d lived in the Alaskan bush for 3 seasons as a fishing guide at remote camps in Bristol Bay. Then 2 years in a rural African village in a subsistence economy where people grew their own food with no semblance of a governmental safety net, starting a successful fish farming program and seeing how 4/5 of the world lives. And now I was armed with a little bit of scientific methodology and statistics. I owe 2/3 of that experience to Don.

Don flew into Ketchikan. Al drove to his high school friend’s place near Bellingham, WA. He left his truck there, and came up on the state ferry MV Columbia to Ketchikan, then he and Don met and came over to Hollis on the Prince of Wales Island ferry. Al and I were good friends when he worked for ADFG in Yakutat. I visited him several times to duck and moose hunt, and to net fish for salmon on the Situk River. It’s been a long time since he’s returned to Alaska, and I hope he can make a habit of it.

We got home from the ferry near dark, so we overnighted in the container cabin. I made the boys a tray of smoked salmon, wasa crackers, and kelp pickles for a late night snack.

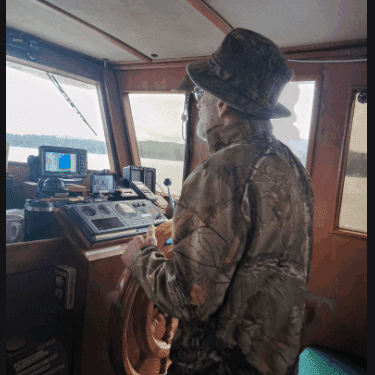

Everyone was up early the next morning. Both boys were up and dressed when I got up, and I thought – this is gonna be a great trip when that happens, as I’m usually the early riser when fishing. We had coffee and took off.

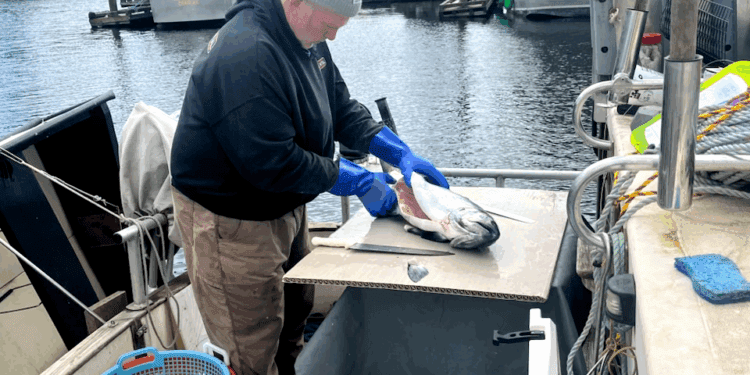

We set the skate at the honey hole and fished nearby. We had steady coho fishing. I trained Al on cleaning fish, and he took over that duty for the rest of the trip. We quit fishing about 3 pm. Don cut his finger somehow and I got him the first aid kit as the bleeding was not wanting to stop. After checking the skate for nothing, we anchored by the pine islands and butchered fish in the pouring rain. I trained Don on scraping the fillet frames from Al with a spoon to get the remaining salmon burger off, and pretty much left the salmon butchering to them for the rest of the trip. I made salmon tail fillets and salad and pasta salad for dinner. Don and Al ate their fill, went to bed early, and both slept hard.

On day 3, everyone was up early again by 5 am, and both boys said how good they slept. We drank coffee for 2 hours, then checked the skate for zip and reset it. We went to the coho drag nearby and put the trolling gear down at 730 am, and caught 3 coho in the first 15 minutes.

By 1230, we had enough salmon for the day already, so went to check the halibut skate. A perfect 34 lber on the skate. We anchored up again in the early afternoon at the spot nearer the outer coast, butchered the fish, then Don got prepping a salmon stir fry with onion, mushroom, and peppers that was just great.

On day 4, we were all up by 530. I weighed anchor straight away to check the skate as it was in the channel where seiners were passing on their way fishing, and I was nervous it might get run over. Nothing on the hooks, and we reset it. We fished the outer island on the lee side, ran over to the chicken hole and fished down to Kelly Cove. We caught a big coho, a chicken halibut and 2 ling cod. When we checked the skate, I broke off a hung anchor on the skate but got the rest of it back. Nothing on the skate. We ran back inside and reset the skate near where we caught the earlier halibut. This time it was first aid time for Al. I just sharpened a dull hook that caught Al’s finger and glove as it went over, and took with it a chunk of Al’s finger. More bleeding and first aid for the crew. We anchored behind the high island in a new spot for me. Don made dinner with salmon burger, making a sort of quiche with bacon, eggs, peppers, onions and mushrooms. Excellent fare, again.

On day 5, we had nothing on the skate, and moved it closer to the high island as the winds were to come up and we didn’t want it in too breezy a place as that’s what cost us the earlier anchor. We caught a king right off the bat, and the winds picked up steadily all day. We scratched a few cohos, then I had enough with the wind on the beam, and we moved to calmer waters between two of the big islands and scratched one fat coho there. Even though we moved the skate, it was too rough to pull it. We ran to the pine islands anchorage after it was too windy behind the high island, and that worked great. I made king salmon, salad, and sauteed vegetables for dinner, and Don said it was the best salmon he’d ever had. Hard to beat fresh king salmon.

One thing of note was that we’d seen hardly any whales this week, which was odd after fishing around them all summer. That made each one we did see a lot more special for the boys.

The next morning, the winds had calmed, and we checked skate first thing for nothing. We fished a new spot by the island where my nephew got his deer in years past, as well as a channel my neighbor told me could be good (it wasn’t), and we finished at the Point Tranquil drag. We scratched a handful of coho, and quit midday, as Don left on the ferry in the morning. We ran to the harbor. After we got the fish and our gear off the boat and put away, Don took us to dinner at the dockside cafe, but Alan demanded to pay.

I went over to Sara’s sister’s house later in the evening. My niece and her friend from Kotzebue were in town to deer hunt and fish. They flew them into an alpine lake, and got a deer, then came back and got some king salmon on the outside waters later in the week. I’d taken over my bag of found reels and was glad the friend took a pile. I’m hoping to go out to Kotzebue late next winter to fish for sheefish through the ice, and she and her family know all about it.

On day 7, we were all up early as usual, and I packed Don’s fish box, being careful not to short his box like I did Tom and Cheese’s boxes. He said it came in at 49 lbs. Then I filled the thermoses with coffee and we were off right on time to the ferry. We arrived at a perfect time when the line was already moving out the door. Don got his ticket and box checked in and was soon walking to the ferry. Al and I were back to Craig before 8 am.

I made a big breakfast when we got back, then we got down to getting our coho catch from the last 2 days butchered to smoke and can. We cut the fillet sides into length-wise strips, then put them into Nevette’s 18 cups water to 2 cups brine for 10 minutes, rinsed off the excess salt, and filled the Big Chief smoker racks. I put the fish in the smoker on just heat (no smoke), and headed to town. I walked my mile dock walk, stopped at the boat and figured out a problem we had with the downrigger and fixed it. Then I went swimming.

I picked up 2 dozen oysters on the way home from Maranda at the pop-up sale she and her newlywed husband were having in the Craig Tribal Hall parking lot. I asked her they were still married 2 weeks out. She laughed. He laughed. They thought I was kidding. Silly kids.

When I got home, Al, an oyster connoisseur from his time on the Texas Gulf Coast and elsewhere down there, ate a bunch raw with hot sauce, then we steamed some for 2 minutes in the instant pot. I put a few cooked oysters with my salad (I’m not a big oyster guy), and Al ate the rest out of the shells. He said they were fantastic. I’l take his word for it.

We took the fish out of the smoker in the early evening. The rainy weather and high humidity didn’t make for much a pellicle forming on the strips, but otherwise they looked okay. Al cut strips to size, which I loaded into jars. I decided to finally take out the big crab cooker stove I garage-saled in Juneau several years ago to can the salmon, rather than using the standard propane cook stove. Good move. It was steaming in just a few minutes under the blast flame of the cooker, and after 10 minutes, I put the 10 lbs pressure cooker weight on the nipple of the lid, and it was rocking immediately. We set our watches for 110 minutes of cook time.

We watched the next to last episode of this season’s Alone show on the History Channel. I watch very little TV or other video, but I’m a big fan of Alone and watched all the episodes. Two women and a man left. And we found out at the end of the show that next week’s show is the last one, so maybe this will be the first time in the “standard” Alone series a woman will win. Many have made it to late in the contest, but get pulled because they lose too much weight to be safe for their health. The two left this season- the first season of the show in a temperate / tropical location in south east Africa – look to be in good shape and in no danger of excessive weight loss.

The first batch of Al’s salmon was in the smoker for about 7 hours, with about an hour of alder smoke on it. The fish looked tasty, but didn’t get much of a pellicle because of the rainy weather. It might not come out as strip pieces, but it’ll eat good. The fillets we cut looked fantastic from our fish care on the boat. The first batch into the jars looked like it was not going to be great. We barely got a pellicle or none at all on some of the strips. This morning I took the jars out and two didn’t seal, and one of those jars broke. We took the fish from those jars in for breakfast. Perfect. All the worry about not perfect smoking on the fish going in was soon allayed by fantastic fish coming out. Again, quality starts at the time of capture. A good fish will be good with most things you do with it, but a poorly handled fish won’t taste very good, regardless of what you do with it. We left the second batch in the smoker on just heat overnight. The rain quit, humidity dropped, and these looked alot nicer. We’ll see if they actually taste better, though. Might be a tad drier than the earlier fish, but it all is going to be great, I’m sure.

I got fish out of the freezer to thaw for canning my smoked salmon. I started cutting off the rib section from the loin of the coho when we butchered them earlier in the season. Sent the loin home with my aunt and the Morgans, and saved the rib sections for me for smoking.